A Reputable Custom Clothing Printing Company for Your Business

MAGICSFASHION is a CHINA-based clothing-printing company that is well-known in the custom printing market among small and local businesses as well as major international corporate clients.

Screen Printing Manufacturing Service

Screen printing, also known as silkscreen or serigraphy, is a popular printing method celebrated for its versatility, durability, and vibrant results. Widely used in textiles, advertising, andart, this printing technique combines precision with creativity, making it a preferred choice across industries.

-

Silk-Screen Printing

Customize nowStencil-based printing process. It involves transferring ink onto a fabric ,through a mesh screen, except in areas blocked by a stencil. Each color in a design is applied separately, requiring multiple screens for multi-colored prints.

-

Water-based Screen Printing

Customize nowSome experts believe that there is a water-related ink technique, this technique is cheaper and more challenging to learn. When done correctly, prints become more durable, softer, and more detailed to the touch than with plastisol inks.

-

Discharge Screen Printing

Customize nowDischarge printing, also known as engraving, refers to the use of discharge agent printed on the colored fabric, the partial pigment has been dyed to destroy, and thus obtain a variety of patterns, patterns of printing method. Discharge agent is a chemical that causes the base of a stain to fade.

-

Foam Screen Printing

Customize nowStrong three-dimensional sense, similar to artificial embroidery, soft feel, wear-resistant, washable, good fastness, and elastic. It can not only be applied on natural fiber fabrics such as cotton, hemp and silk, but also on artificial fiber fabrics.

-

Foil Screen Printing

Customize nowFirstly, using this printing technique, a certain kind of glue helps to print a design on fabrics. The foil is then bonded to the glue with the help of a heat press. Pressure and heat work together to seal the foil before any surplus is removed. If properly designed, foil-printed t-shirts can have a striking appearance. It gives art new vitality.

-

Glow In The Dark Screen Printing

Customize nowThe printing procedure is the same for printing that glows in the dark. The use of a unique glow-in-the-dark ink is the only distinction. These methods are utilized to create wacky and fascinating visuals that make a fashion statement.

Leading Direct-to-Garment (DTG) Printing manufacturer for your brand

MAGICSFASHION offers Direct-to-Garment (DTG) Printing services that supports you to extend your designs and respond more flexibly to the challenges of your competitors.

Direct-to-Garment (DTG) Printing Manufacturer

DTG printing uses a specialized inkjet printer to apply water-based inks directly onto fabric. The printer sprays the ink onto the material in precise amounts, allowing for photorealistic designs with vibrant colors and intricate details. The process is digital, meaning there’s no need for screens or plates, making it ideal for on-demand printing and small production runs.This technique is especially effective for cotton fabrics, although advancements in technology have expanded its use to blends and other natural fibers.

Advantages of Direct-to-Garment (DTG) Printing

High-Quality Prints: DTG produces photorealistic, detailed designs with a wide color gamut and smooth gradients.

- No Minimum Orders: Unlike screen printing, DTG doesn’t require setup costs, making it cost-effective for single items or small batches.

- Eco-Friendly: Water-based inks used in DTG printing are often non-toxic and environmentally friendly. Additionally, the digital process reduces waste compared to traditional methods.

- On-Demand Printing: DTG allows for quick production of customized garments, catering to e-commerce trends and personalized products.

- Ease of Use: The fully digital process requires minimal manual labor and allows for easy modifications to designs.

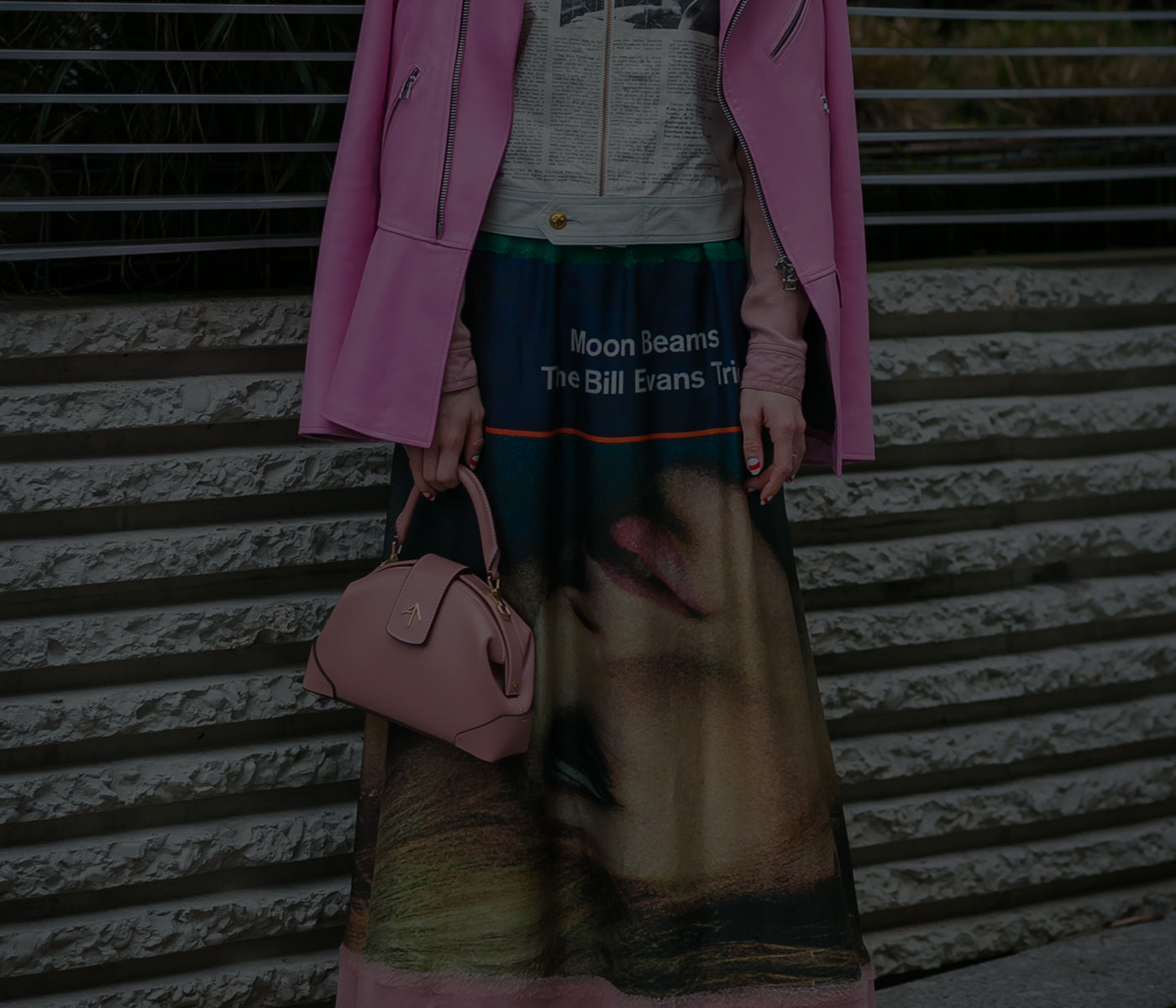

Sublimation Printing can support your rich imagination

Sublimation printing has emerged as a transformative technique in the world of textile and merchandise printing, celebrated for its ability to produce vibrant, high-quality, and durable designs. This method is particularly popular among designers and businesses for creating personalized items, promotional products, and high-fashion apparel.

Sublimation Printing Manufacturer

Sublimation is widely used for sportswear, activewear, shirt,dress,and custom T-shirts due to its ability to print vibrant, all-over designs.

Advantages of Sublimation Printing

Vibrant Colors and Detail: Sublimation printing produces sharp, photorealistic images with a wide color gamut, making it ideal for intricate designs and gradients.

- Durability: The design becomes part of the material, ensuring it won’t peel, crack, or fade, even after multiple washes.

- Versatility: Sublimation suitable for all kinds of chemical fiber fabrics.

- Full Coverage: Unlike some printing methods, sublimation allows for edge-to-edge printing on fabrics .

- Eco-Friendly: Since it doesn’t require additional chemicals or water for the process, sublimation printing is considered an environmentally friendly option.

Vinyl Heat Transfer Printing gives customers more three-dimensional more diversified visual effects

Vinyl Heat Transfer Printing (VHTP) is a widely embraced technique in the textile industry, celebrated for its simplicity, versatility, and vibrant results. Whether you're a seasoned designer or an enthusiast starting out, this method offers a reliable way to bring your ideas to life on fabric.

Vinyl Heat Transfer Printing Manufacturing service

Vinyl Heat Transfer Printing involves cutting a design from sheets of colored vinyl and applying it to a substrate—typically fabric—using a heat press machine. The vinyl has a heat-activated adhesive backing that bonds securely to the material under the right combination of heat, pressure, and time.This process is straightforward yet capable of producing professional-grade results. It is particularly popular for creating customized apparel, such as T-shirts, hoodies, and sportswear.

Advantages of Vinyl Heat Transfer Printing

Vivid and Precise Designs: VHTP produces sharp, vibrant results, making it ideal for logos, text, and bold graphics.

- Durability: Vinyl designs are resistant to fading, cracking, and peeling, even after repeated washing.

- Versatility: This technique works well on a wide range of materials, including cotton, polyester, and blends. Vinyl can also be layered for multi-color effects or combined with other printing techniques.

- Customization: VHTP is perfect for on-demand or small-batch production, making it a favorite for personalized apparel, team uniforms, and promotional items.

- Low Setup Cost: Compared to screen printing, VHTP requires minimal equipment, making it accessible for small businesses and hobbyists.